Product Description:

The Boiler Tubular Membrane Wall is a crucial component in boiler systems, providing efficient heat transfer and structural support. Known for its durability and reliability, the membrane wall plays a key role in maintaining optimal performance in various industrial applications.

Constructed using high-quality materials and advanced manufacturing techniques, the membrane wall is designed to withstand high temperatures and pressures. The welding technique employed in the fabrication process is Submerged Arc Welding, ensuring strong and seamless joints that enhance the overall integrity of the structure.

The Boiler Tubular Membrane Wall is engineered to operate within a temperature range of up to 600°C, making it suitable for a wide range of boiler systems. Its ability to withstand high temperatures without compromising performance makes it an ideal choice for demanding industrial environments.

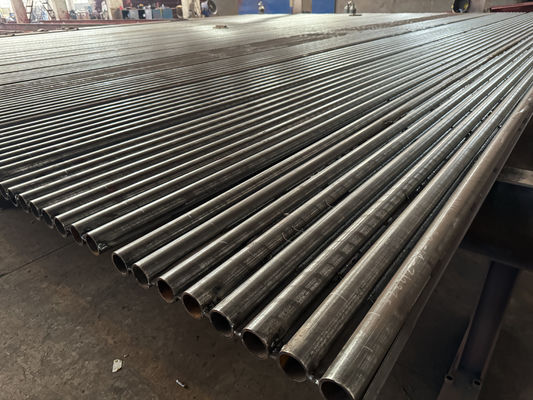

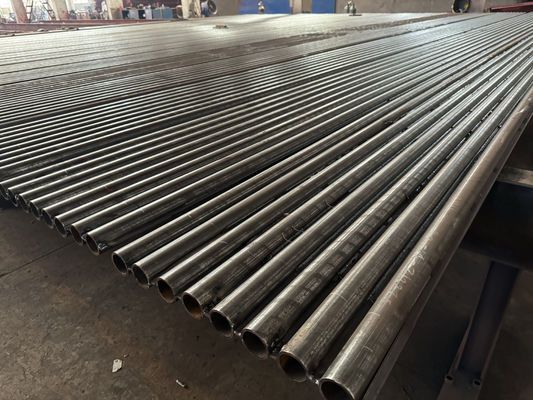

The dimension of the tube used in the membrane wall is 38.1*3.2, providing a balance of strength and heat transfer efficiency. This optimal size allows for effective heat exchange while maintaining structural stability, contributing to the overall efficiency of the boiler system.

When it comes to fuel compatibility, the membrane wall is designed to work seamlessly with coal, gas, and oil-fired boilers. Whether the system is fueled by coal, gas, or oil, the membrane wall ensures efficient heat transfer and reliable performance, catering to diverse fuel requirements.

In addition to its versatility in fuel options, the membrane wall is also adept at handling water heat, further enhancing its applicability in different boiler configurations. The water-cooled design of the membrane wall allows for efficient heat removal, contributing to the overall energy efficiency of the system.

Whether operating at low or high pressure, the Boiler Tubular Membrane Wall excels in maintaining structural integrity and heat transfer efficiency. Its robust construction and reliable performance make it a preferred choice for both low-pressure and high-pressure boiler systems, ensuring consistent operation under varying conditions.

In summary, the Boiler Tubular Membrane Wall, also known as the Membrane Wall Boiler Panel or Water-Cooled Membrane Wall, is a critical component in boiler systems that offers durability, efficiency, and versatility. With its Submerged Arc Welding technique, high-temperature tolerance, optimal tube dimensions, fuel compatibility, and pressure handling capabilities, the membrane wall provides reliable heat transfer and structural support in diverse industrial applications.

Features:

-

Product Name: Boiler Membrane Wall

-

Temperature Range: Up To 600°C

-

Welding Way: Submerged Arc Welding

-

Welding Technique: Submerged Arc Welding

-

Pressure: Low/High Pressure

-

Materials: Carbon Steel / Stainless Steel

Technical Parameters:

|

Installation Method

|

Welding

|

|

Fuel

|

Coal/Gas/Oil-fired, Water Heat

|

|

Flexibility

|

High

|

|

Processing Technology

|

Welding

|

|

Condition

|

New

|

|

Dimension Of Tube

|

38.1*3.2

|

|

Pressure

|

Low/High Pressure

|

|

Tube Material

|

SA 210 A1

|

|

Temperature Range

|

Up To 600°C

|

|

Surface Treatment

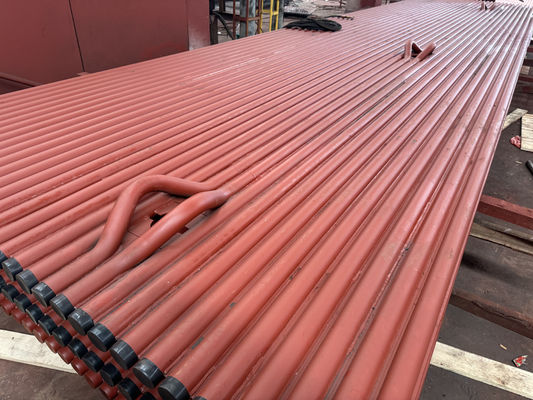

|

Painting

|

Applications:

Boiler Sealed Membrane Wall is a crucial component in boiler systems, providing a barrier between the heat source and the water or steam circulating inside. The product boasts a tube dimension of 38.1*3.2, ensuring efficient heat transfer and structural integrity. Utilizing Submerged Arc Welding, the seams are securely joined, enhancing the overall durability and performance of the membrane wall.

Designed for both low and high-pressure applications, the Boiler Sealed Membrane Wall is versatile and suitable for various industrial settings. Whether it's a small-scale operation requiring low pressure or a heavy-duty industrial process demanding high pressure, this product meets the requirements with ease.

The surface treatment of Painting not only enhances the aesthetic appeal of the membrane wall but also provides protection against corrosion and environmental elements. This ensures a longer lifespan and sustained efficiency, making it a cost-effective solution for boiler systems.

Manufactured by a specialized Boiler Membrane Wall Manufacturer, this product is crafted with precision and expertise. The manufacturer's experience and dedication to quality guarantee a reliable and high-performance product that meets industry standards.

Product Application Occasions and Scenarios:

- Industrial Boiler Systems: The Boiler Sealed Membrane Wall is ideal for industrial boilers used in various sectors such as manufacturing, power generation, and chemical processing. Its ability to withstand high temperatures and pressures makes it a reliable choice for demanding applications.

- Power Plants: In power generation facilities, where efficiency and reliability are paramount, the Boiler Sealed Membrane Wall excels. Its sturdy construction and effective heat transfer properties contribute to the overall performance of the boiler system, ensuring seamless operation.

- Petrochemical Industry: For processes involving high temperatures and harsh operating conditions, the Boiler Sealed Membrane Wall provides the necessary protection and efficiency. Its resistance to corrosion and structural stability make it a valuable component in petrochemical plants.

Overall, the Boiler Sealed Membrane Wall is a versatile and reliable product that caters to a wide range of industrial applications. With its superior design, welding technique, pressure capabilities, and surface treatment, it offers a cost-effective solution for enhancing the performance and longevity of boiler systems.

Customization:

Our Product Customization Services for the Boiler Membrane Wall include:

Materials: Carbon Steel / Stainless Steel

Model: Boiler Part

Dimension Of Tube: 38.1*3.2

Fuel: Coal/Gas/Oil-fired, Water Heat

Flexibility: High

Our customization services cater to water-cooled membrane wall solutions, boiler membrane wall variations, and furnace membrane wall system designs to meet your specific requirements.

Support and Services:

Our Product Technical Support team for the Boiler Membrane Wall product is dedicated to providing expert assistance and guidance to our customers. We offer comprehensive services to ensure optimal performance and reliability of the product. Our team is available to answer any technical questions, troubleshoot issues, and provide recommendations for maintenance and optimization.

Packing and Shipping:

Product Name: Boiler Membrane Wall

Description: High-quality membrane walls for boilers, designed to enhance heat transfer efficiency.

Package Contents: 1 Boiler Membrane Wall

Package Dimensions: 40cm x 30cm x 10cm

Shipping Method: Standard Shipping

Shipping Time: 5-7 business days

FAQ:

Q: What is a Boiler Membrane Wall?

A Boiler Membrane Wall is a type of water-cooled wall construction used in industrial boilers to improve heat transfer efficiency.

Q: What are the advantages of using a Boiler Membrane Wall?

Boiler Membrane Walls offer high thermal efficiency, better insulation, reduced heat loss, and increased boiler lifespan.

Q: How does a Boiler Membrane Wall work?

A Boiler Membrane Wall consists of tubes welded together to form a continuous membrane that creates a barrier between the combustion chamber and the boiler water.

Q: Can a Boiler Membrane Wall be customized for different boiler sizes?

Yes, Boiler Membrane Walls can be customized to fit different boiler sizes and configurations to meet specific industrial requirements.

Q: How often should a Boiler Membrane Wall be inspected for maintenance?

Regular inspection and maintenance of Boiler Membrane Walls are recommended at least once a year to ensure optimal performance and longevity of the boiler system.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!