Product Description:

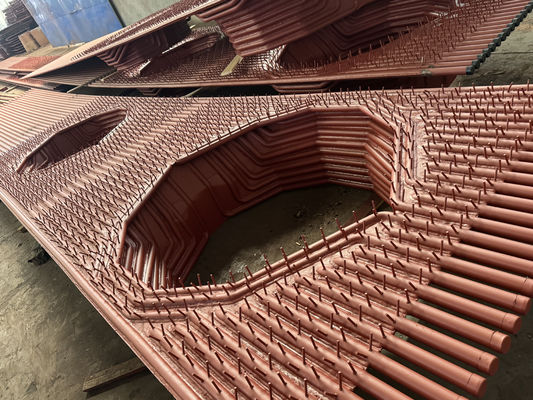

The Boiler Membrane Wall is an essential component in boiler systems, providing high flexibility and reliable performance. Designed to withstand high temperatures and pressures, this product is ideal for various industrial applications.

With a high level of flexibility, the Boiler Membrane Wall is able to adapt to different boiler designs and configurations, ensuring seamless integration into existing systems. This flexibility allows for easy installation and maintenance, reducing downtime and enhancing overall efficiency.

Compatible with coal, gas, and oil-fired boilers, the Boiler Membrane Wall is a versatile solution for a wide range of fuel types. Whether used for water heating or steam generation, this product delivers consistent and efficient performance, making it a preferred choice for many industries.

The welding way employed in the production of the Boiler Membrane Wall is Submerged Arc Welding, a process known for its precision and strength. This welding technique ensures a tight and secure bond between the tubes and the membrane wall, enhancing the structural integrity and longevity of the product.

Constructed using SA 210 A1 tube material, the Boiler Membrane Wall offers excellent corrosion resistance and thermal conductivity. This high-quality material is specifically chosen for its durability and reliability in demanding boiler environments, making it a trusted choice for industrial applications.

Furthermore, the welding technique of Submerged Arc Welding is meticulously applied to every seam and joint of the Boiler Membrane Wall, guaranteeing a leak-proof and robust construction. This attention to detail ensures that the product can withstand extreme conditions and maintain its performance over an extended period.

The Boiler Membrane Wall, also known as Boiler Sealed Membrane Wall, is designed to optimize heat transfer and enhance energy efficiency in boiler systems. By providing a sealed barrier between the furnace and the boiler water, this membrane wall minimizes heat loss and improves overall thermal performance.

In conclusion, the Boiler Membrane Wall is a superior product that offers high flexibility, compatibility with various fuels, precise welding techniques, and durable tube material. With its exceptional design and construction, this product is a reliable and efficient solution for industrial boiler systems.

Features:

-

Product Name: Boiler Membrane Wall

-

Welding Technique: Submerged Arc Welding

-

Temperature Range: Up To 600°C

-

Fuel: Coal/Gas/Oil-fired, Water Heat

-

Pressure: Low/High Pressure

-

Processing Technology: Welding

Technical Parameters:

|

Welding Technique

|

Submerged Arc Welding

|

|

Manufacturer

|

Specialized Boiler Membrane Wall Manufacturer

|

|

Model

|

Boiler Part

|

|

Condition

|

New

|

|

Surface Treatment

|

Painting

|

|

Tube Material

|

SA 210 A1

|

|

Flexibility

|

High

|

|

Materials

|

Carbon Steel / Stainless Steel

|

|

Installation Method

|

Welding

|

|

Fuel

|

Coal/Gas/Oil-fired, Water Heat

|

Applications:

The Boiler Membrane Wall product with surface treatment of painting is a crucial component in various industrial boilers. Its dimension of 38.1*3.2 makes it suitable for different boiler sizes and configurations.

Designed to withstand high temperatures up to 600°C, this Water-Cooled Membrane Wall plays a vital role in ensuring efficient heat transfer within the boiler system. The advanced welding technique of submerged arc welding guarantees a strong and durable construction, making it a reliable choice for new boiler installations.

The Boiler Tubular Membrane Wall is ideal for applications where a high level of heat resistance and structural integrity is required. Its painted surface treatment not only enhances its corrosion resistance but also provides a clean and professional appearance.

Whether used in industrial power plants, refineries, or other facilities requiring steam generation, the Membrane Wall Boiler Panel excels in maintaining optimal boiler performance. Its precise dimensions and quality welding ensure a perfect fit within the boiler system, contributing to overall efficiency and reliability.

With its ability to handle extreme temperatures and harsh operating conditions, this Boiler Membrane Wall is suitable for a wide range of application occasions. From coal-fired boilers to biomass boilers, this product serves as a critical component in ensuring safe and efficient heat exchange processes.

Whether in new boiler installations or as a replacement part in existing systems, the Boiler Membrane Wall with its painted surface treatment, precise dimensions, and superior welding technique offers a dependable solution for various industrial boiler requirements.

Customization:

For our Furnace Membrane Wall System, we offer Product Customization Services for the Boiler Membrane Wall, specifically tailored to meet your needs:

- Welding Technique: Submerged Arc Welding

- Tube Material: SA 210 A1

- Dimension Of Tube: 38.1*3.2

- Surface Treatment: Painting

- Condition: New

Enhance your Boiler Tubular Membrane Wall with our tailored customization services today!

Support and Services:

The Product Technical Support and Services for the Boiler Membrane Wall product include:

- Installation guidance and support to ensure proper setup of the membrane wall system.

- Troubleshooting assistance to address any issues that may arise during operation.

- Maintenance recommendations to prolong the lifespan of the membrane wall and ensure efficient performance.

- Training programs for operators to enhance their understanding of the system and optimize its usage.

Packing and Shipping:

Product Packaging:

The Boiler Membrane Wall product is carefully packaged in a sturdy cardboard box to ensure its safety during transit. Each piece is wrapped in protective bubble wrap to prevent any damage. The packaging is designed to withstand rough handling and transportation.

Shipping:

Orders for the Boiler Membrane Wall product are typically shipped via a reliable courier service. Customers can expect their orders to be shipped within 1-2 business days after purchase. Tracking information will be provided so that customers can monitor the status of their delivery. The product will be delivered directly to the customer's specified address.

FAQ:

Q: What is a Boiler Membrane Wall?

A Boiler Membrane Wall is a type of wall structure in a boiler that is made up of tubes welded together to form a membrane. It helps in enhancing heat transfer and increasing boiler efficiency.

Q: What are the advantages of using a Boiler Membrane Wall?

Using a Boiler Membrane Wall can improve thermal efficiency, reduce heat loss, enhance structural integrity, and increase the lifespan of the boiler.

Q: How is a Boiler Membrane Wall installed?

The installation process of a Boiler Membrane Wall involves welding the tubes together to form a membrane structure that is then fitted inside the boiler during the construction or maintenance process.

Q: What materials are used to manufacture Boiler Membrane Walls?

Boiler Membrane Walls are typically made of high-quality alloy steel or carbon steel tubes that are suitable for high-temperature and high-pressure applications.

Q: How can I maintain a Boiler Membrane Wall?

To maintain a Boiler Membrane Wall, regular inspection for any signs of corrosion, leaks, or damage is recommended. Cleaning the wall periodically and ensuring proper water chemistry in the boiler can also help in prolonging its lifespan.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!